Why Commercial Kitchens Rely on Urethane Epoxy Flooring: The Superior System for Demanding Environments

Commercial kitchens operate in one of the toughest environments imaginable. Floors are exposed daily to extreme temperatures, heavy traffic, constant moisture, and aggressive cleaning routines. Between rolling carts, dropped utensils, grease, and steam, traditional flooring materials like tile or vinyl simply can’t keep up.

That’s why more food service operators and facility managers are switching to urethane epoxy flooring systems — the high-performance hybrid that combines the strength and adhesion of epoxy with the thermal and chemical resistance of urethane cement. The result is a seamless, sanitary, and incredibly durable surface built specifically for demanding food preparation environments.

What Makes Urethane Epoxy Flooring Different

Urethane epoxy flooring systems, also called urethane cement or urethane mortar floors, are multi-layered coatings engineered to handle the intense conditions of commercial kitchens and food processing plants.

While standard epoxy coatings are strong, they can become brittle under heat or moisture. Urethane epoxy, on the other hand, expands and contracts with the concrete substrate, maintaining its bond even under steam cleaning, hot water, or rapid temperature shifts.

These systems combine the best of both worlds:

- A urethane cement base that provides flexibility, shock absorption, and extreme heat resistance.

- A high-performance epoxy or urethane topcoat that delivers chemical resistance, gloss, and easy cleanability.

Together, they form one of the most durable and hygienic flooring systems available for commercial kitchens today.

Key Advantages of Urethane Epoxy Flooring for Commercial Kitchens

1. Handles Extreme Temperature Changes (Thermal Shock Resistance)

Commercial kitchens routinely face rapid temperature swings — from freezers to steam kettles and hot washdowns. Standard epoxies can crack or delaminate under these conditions, but urethane epoxy systems are designed to withstand thermal shock. They maintain integrity and adhesion even under boiling water, hot oil spills, or high-pressure steam cleaning.

2. Exceptional Chemical and Acid Resistance

From vinegar and citrus juices to caustic degreasers and sanitizers, food service facilities expose floors to harsh substances daily. Urethane epoxy systems resist acids, alkalis, oils, and solvents, preventing surface damage, staining, or corrosion. This makes them ideal for kitchens, breweries, and food manufacturing environments that demand constant sanitation.

3. Seamless, Non-Porous, and Hygienic Surface

Unlike tile floors that trap bacteria in grout lines, urethane epoxy floors form a monolithic, non-absorbent surface with no joints or seams. This seamless design eliminates places for bacteria, mold, and mildew to grow — ensuring compliance with USDA, FDA, and local health codes.

Cleaning is simple: just sweep, rinse, and mop. No grout repair, waxing, or sealing required.

4. Slip-Resistant and Safe for Workers

Kitchen floors are frequently wet or greasy, creating potential slip hazards. Urethane epoxy coatings can be customized with textured additives or quartz broadcast layers to enhance traction and keep workers safe.

These anti-slip finishes provide grip without trapping dirt, balancing safety with hygiene and easy maintenance.

5. Built for Heavy Impact and Constant Traffic

Rolling carts, pallet jacks, and heavy kitchen equipment can cause severe wear on traditional floors. Urethane epoxy systems cure into a dense, impact-resistant surface that won’t chip, dent, or deform under pressure.

The system’s compressive strength often exceeds that of concrete itself — ensuring the floor remains smooth and strong, even in high-traffic zones.

6. Long-Lasting, Low-Maintenance Performance

Urethane epoxy floors are known for their longevity and minimal upkeep. They resist delamination, staining, and fading, maintaining a clean appearance for years with simple routine cleaning.

Because they rarely need replacement or patching, they offer an excellent return on investment by minimizing downtime, maintenance costs, and disruption to daily operations.

7. Easy Compliance with Health and Safety Regulations

Food-handling areas require non-absorbent, easily sanitized, and slip-resistant floors. Urethane epoxy systems meet and exceed health code requirements, helping kitchens stay compliant with strict inspection standards.

By maintaining a sanitary surface that’s easy to disinfect, these systems help facilities pass inspections effortlessly while protecting their reputation for cleanliness and safety.

8. Comfortable for Staff During Long Shifts

Although urethane epoxy is incredibly tough, it provides slight shock absorption and flexibility underfoot — reducing fatigue for employees who spend hours standing.

This ergonomic benefit improves comfort, reduces strain on joints, and enhances productivity, making it a smart investment for both facility owners and their teams.

9. Sustainable and Environmentally Friendly

Urethane epoxy systems are not only long-lasting but also eco-conscious. Their extended service life reduces waste and replacement frequency, and many modern formulations are low-VOC, supporting indoor air quality and green building standards.

Because they bond directly to existing concrete, they also eliminate the need for demolition or new material production — reducing environmental impact.

Why Urethane Epoxy Is the Gold Standard for Commercial Kitchens

When it comes to food service environments, no flooring system offers the same combination of performance, safety, and sanitation as urethane epoxy. It resists heat, moisture, and harsh cleaning agents, all while maintaining a seamless, slip-resistant surface that looks great and lasts for decades.

That’s why it’s the go-to choice for:

- Restaurants and catering kitchens

- Food and beverage production plants

- Breweries and dairies

- Institutional kitchens and cafeterias

- Bakeries, butcheries, and cold storage facilities

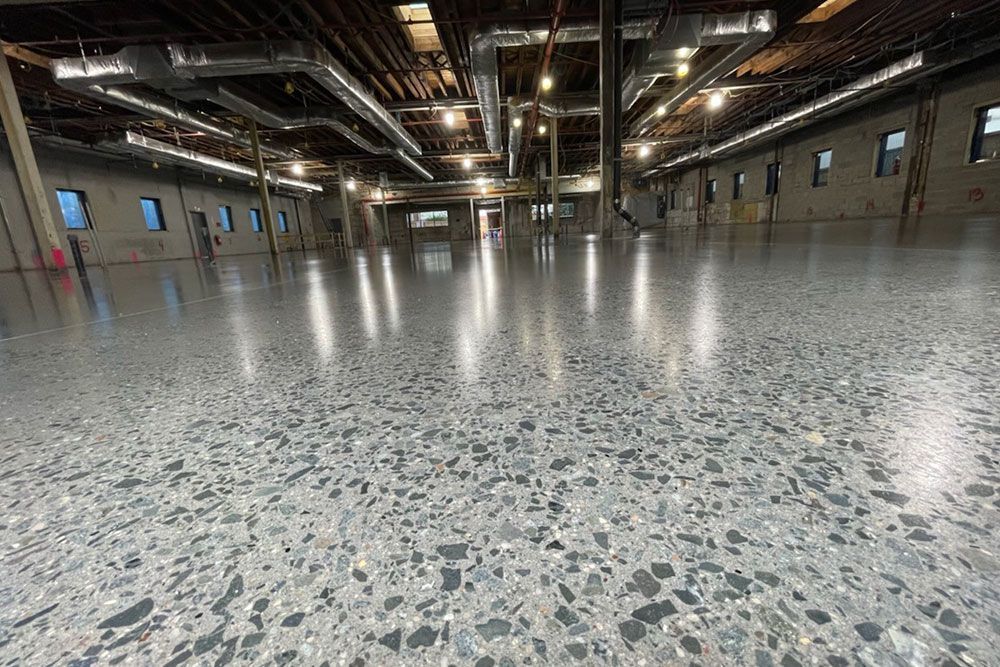

Upgrade Your Kitchen Floors with Premier Polishing Corp

If your facility needs a durable, sanitary, and thermally resistant flooring system, Premier Polishing Corp is your trusted partner for urethane epoxy installations in Long Island, NY.

Our in-house civil engineers and trained crews bring over 75 years of combined experience, ensuring every floor is installed with precision and care. We use only top-tier materials and advanced surface preparation techniques to guarantee superior adhesion, performance, and longevity.

Beyond urethane epoxy systems, we also offer:

- Polished concrete and

grind & seal finishes

- Microtopping and overlay applications

- Epoxy and hybrid floor coatings

- Custom concrete countertops, tables, and furniture

Every project is handled entirely in-house — from logistics to installation — to maintain consistent quality and reliable communication for every client.

Contact

Premier Polishing Corp today to design and install a

urethane epoxy floor system that elevates your commercial kitchen’s durability, hygiene, and performance for years to come.