Comparing The Most Common Types Of Commercial Concrete Floor Coatings

The performance and appearance of a concrete floor depend greatly on the protective coating applied to its surface. Concrete on its own provides an exceptionally strong foundation, but the right coating system enhances that strength — improving durability, safety, and overall aesthetics.

Selecting the proper material for your facility ensures resistance to traffic, chemicals, and environmental conditions, preventing premature wear and costly repairs. With the right preparation and professional application, these coatings can deliver decades of reliable performance while maintaining a clean, attractive environment for employees and visitors alike.

Epoxy Coatings for Commercial Concrete Floors

Epoxy coatings remain one of the most popular options for commercial and industrial applications thanks to their unmatched toughness and chemical resistance. These coatings form a seamless, non-porous surface that resists liquid absorption and stands up to frequent cleaning.

You’ll find epoxy systems in warehouses, manufacturing plants, and commercial kitchens — anywhere heavy traffic, spills, or machinery are common. Facility managers appreciate epoxy’s resistance to chipping, peeling, and thermal fluctuations, as well as its smooth, easy-to-clean finish.

Epoxy floors also support hygiene standards in healthcare and food service environments and can be customized with decorative colors or vinyl chips for an enhanced visual appeal.

Polyurethane Coatings for Abrasion and Chemical Resistance

Polyurethane coatings excel in high-impact and high-abrasion environments. Their flexible structure helps absorb shocks from dropped tools or moving vehicles, outperforming many rigid epoxy systems.

Often used as a topcoat, polyurethane enhances the lifespan of an existing floor system while providing superior resistance to solvents, automotive fluids, and aggressive cleaning agents. Another key advantage: polyurethane retains its gloss and color even under UV exposure, making it ideal for spaces with sunlight or outdoor elements.

The result is a long-lasting, low-maintenance surface that reduces the need for frequent recoating and maintains a clean, professional appearance.

Polyaspartic Coatings for Fast Installation and Long-Term Durability

When downtime is limited, polyaspartic coatings deliver speed and strength. These advanced coatings cure rapidly, often allowing facilities to return to service within hours rather than days.

Polyaspartic systems are applied thicker than many alternatives, creating a dense, protective finish capable of withstanding heavy traffic and machinery. They also remain flexible in extreme temperatures, resisting cracking and peeling while maintaining excellent UV and chemical resistance.

Perfect for 24-hour operations such as retail centers or production facilities, polyaspartic coatings combine durability, efficiency, and visual appeal in one high-performance solution.

Acrylic Sealers for Basic Concrete Protection

Acrylic sealers offer a cost-effective solution for light-duty environments where basic protection and aesthetic enhancement are the primary goals. These liquid sealers penetrate the concrete to form a thin barrier that minimizes dusting and helps control moisture absorption.

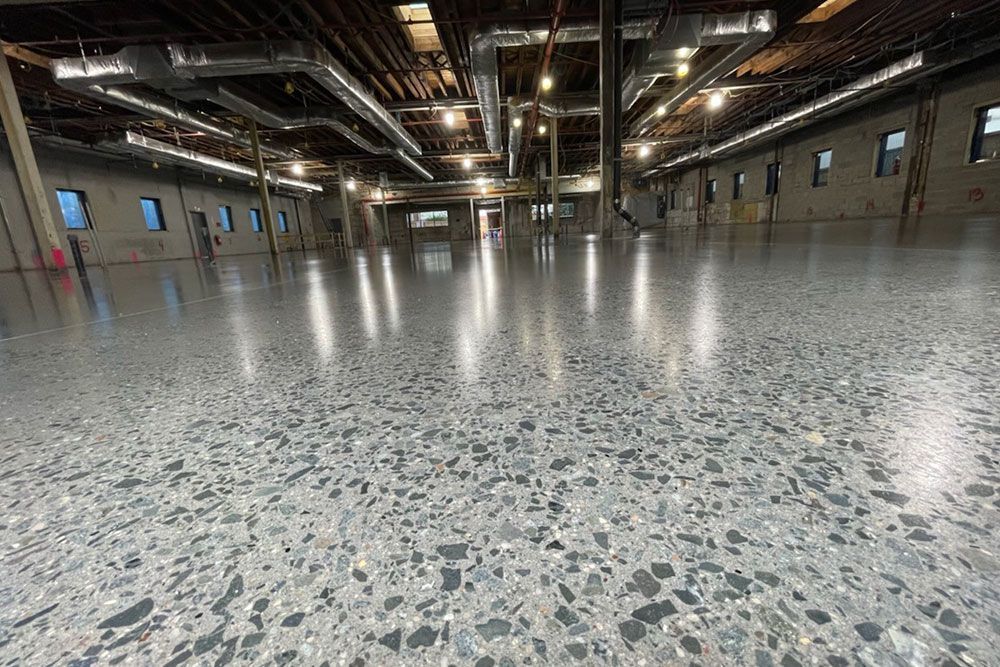

Commonly used in walkways, patios, and low-traffic areas, acrylic sealers also enhance the color of stained or exposed aggregate surfaces, providing a brighter, more polished look. However, because the film is thin, it requires periodic reapplication and is not recommended for heavy industrial or chemical-use areas.

Metallic Epoxy Coatings for Decorative and High-End Spaces

Metallic epoxy coatings merge durability with design, using metallic pigments mixed into clear epoxy to create a mesmerizing, three-dimensional effect. The application process involves swirling and layering techniques that mimic the look of flowing water or polished stone.

These floors are ideal for showrooms, lobbies, and retail spaces, where aesthetics matter as much as performance. In addition to their visual appeal, metallic epoxies maintain the same chemical and abrasion resistance as standard epoxy systems, while their reflective finish brightens interior lighting for a more vibrant atmosphere.

Quartz-Filled Coatings for Slip Resistance and Hygiene

Quartz-filled systems combine safety, durability, and cleanliness in one seamless floor. During installation, technicians broadcast fine quartz granules into an epoxy or polymer base to create a textured, slip-resistant surface.

These coatings are perfect for wet or high-risk areas like commercial kitchens, locker rooms, and pool decks. The quartz texture enhances traction, while the seamless, non-porous finish prevents moisture penetration and bacterial growth.

Durable enough to handle heavy foot traffic and equipment, quartz systems are a top choice for food and beverage industries focused on hygiene and worker safety.

Flake Flooring Systems for Impact Resistance and Style

Flake flooring systems use decorative vinyl chips broadcast into a wet base coat to create a multi-colored, speckled look. The flakes add texture and disguise imperfections while improving the floor’s impact resistance.

With excellent slip resistance and easy maintenance, flake floors are a popular option for garages, kitchens, retail centers, and institutional hallways. They offer a stylish, durable solution that balances performance and visual interest — available in countless color and size combinations.

Urethane Cement Coatings for Food and Beverage Facilities

For environments exposed to extreme conditions, urethane cement coatings deliver unmatched performance. Specifically designed for the food and beverage industry, these coatings resist thermal shock, hot water, and harsh sanitizers that can damage standard epoxy floors.

Their dense, seamless structure prevents microbial growth and withstands aggressive cleaning chemicals, while maintaining slip resistance in wet environments. Urethane cement systems comply with stringent food safety regulations and provide a long-lasting, sanitary surface for demanding production areas.

Self-Leveling Concrete Overlays for Uneven Floors

Self-leveling overlays are an excellent way to restore and level damaged or uneven concrete slabs without a full replacement. These cementitious materials flow smoothly across the surface, filling low areas and creating a strong, even base for subsequent coatings or floor coverings.

They bond tightly to existing concrete, providing a durable foundation for epoxy, tile, or polished concrete finishes. This cost-effective repair method saves time and money while revitalizing old floors for new use.

Stamped Concrete Overlays for Decorative Patterned Designs

Stamped concrete overlays combine durability with design versatility, recreating the appearance of natural stone, brick, or wood at a fraction of the cost. Installers apply a thin cementitious overlay, then imprint it with texture mats before curing to achieve realistic, three-dimensional patterns.

Perfect for entryways, plazas, and retail walkways, these overlays provide long-lasting beauty and weather resistance for both interior and exterior applications. Businesses choose stamped overlays to elevate their spaces without the expense of natural materials.

Chemical-Resistant Coatings for Harsh Industrial Environments

In chemical manufacturing or research facilities, specialized chemical-resistant coatings provide essential protection for concrete surfaces. These advanced polymer systems form an impermeable barrier that prevents corrosive substances from damaging the underlying structure.

Tailored to specific chemical exposures — from acids and alkalis to solvents — these coatings maintain integrity under thermal stress, abrasion, and heavy use. They’re a crucial safeguard for battery rooms, laboratories, and chemical plants, ensuring both safety and compliance while extending the life of the facility’s flooring system.

Partner With Premier Polishing Corp for Industrial Concrete Floor Resurfacing in Long Island, NY

Ready to upgrade your commercial floors? At Premier Polishing Corp, we help businesses throughout Long Island, NY choose the best coating systems for their specific needs — from epoxy and urethane cement to polished concrete and microtopping overlays.

Our in-house civil engineers and technicians bring over 75 years of combined experience, using advanced equipment and proven methods to deliver superior performance and finish quality.

In addition to flooring, we also create custom concrete countertops, fire surrounds, sinks, and outdoor furniture, crafted with precision and care. From initial consultation to final inspection, our team manages every step with professionalism and attention to detail — ensuring your flooring investment looks exceptional and lasts for decades.