What You Should Know About Commercial Concrete Polishing

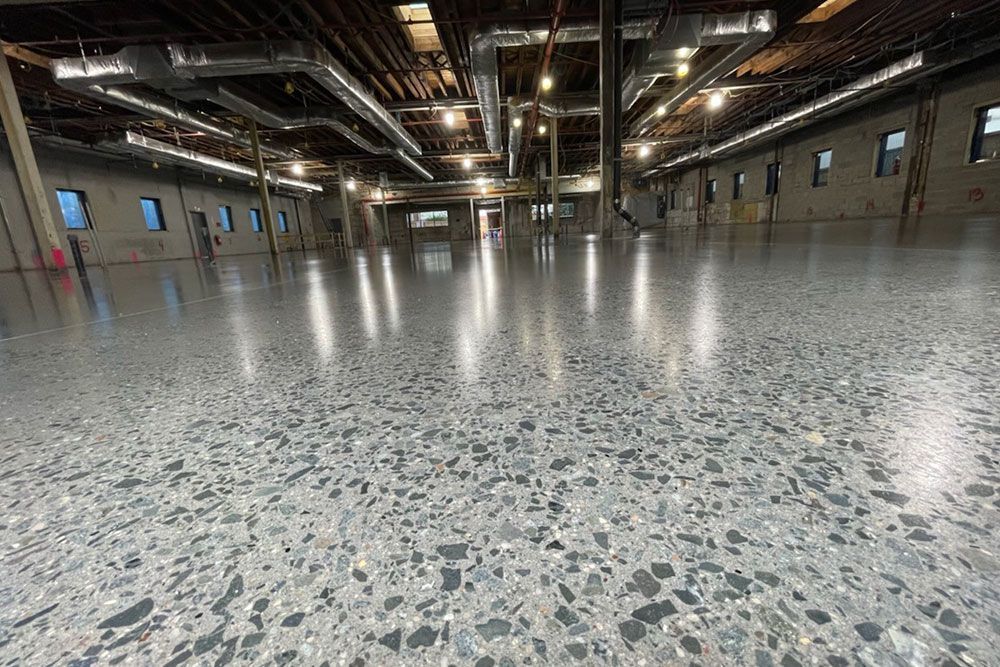

The look and condition of a commercial space directly influence both client impressions and employee satisfaction. For this reason, more business owners and facility managers are turning to concrete polishing — a flooring solution that combines visual sophistication with long-term strength and ease of maintenance.

Polished concrete floors transform existing slabs into sleek, durable surfaces that resist stains, abrasions, and heavy foot traffic. With minimal downtime during installation and years of reliable performance, polished concrete offers one of the most cost-effective and attractive flooring options for today’s commercial and industrial environments.

The Basic Process of Commercial Concrete Polishing

Concrete polishing is both a science and a craft. The process begins with a thorough cleaning and repair of the existing concrete to remove debris, patch cracks, and fix spalls.

Next, technicians grind the floor using diamond-impregnated pads, gradually refining the surface through multiple passes. Each stage removes imperfections and smooths the concrete to the desired level.

A chemical hardener is then applied to penetrate the surface, densify the material, and increase resistance to dusting and wear. Finally, the concrete is polished using progressively finer tools until it achieves the desired sheen — from a soft satin glow to a high-gloss, mirror-like finish. The result is a smooth, reflective surface that’s both elegant and durable.

Key Benefits of Polished Concrete in Commercial Settings

Polished concrete provides a wide range of functional and financial advantages for commercial properties:

- Exceptional durability: The hardened surface resists heavy foot traffic, machinery movement, and impact, making it ideal for high-use areas like warehouses, offices, and retail stores.

- Low maintenance: Its seamless, non-porous finish makes cleaning effortless — requiring only routine sweeping and the occasional damp mop with a neutral cleaner.

- Cost efficiency: With no need for waxing, stripping, or resurfacing, ongoing maintenance costs remain significantly lower than for other flooring types.

- Healthier environment: The smooth surface prevents dust buildup and allergen retention, improving indoor air quality and cleanliness.

- Modern, customizable aesthetics: Polished concrete can be tailored to your brand and design vision, with different aggregate exposures, sheens, and stain colors creating endless design possibilities.

In short, polished concrete offers a balance of beauty, resilience, and practicality that few flooring systems can match.

How to Select a Commercial Concrete Polishing Contractor

Choosing the right contractor is critical to ensuring a high-quality, long-lasting floor. Look for professionals who:

- Have proven experience in large-scale commercial polishing projects.

- Are fully licensed, insured, and trained in the latest techniques and safety standards.

- Use industrial-grade tooling and materials from reputable manufacturers.

- Provide references or project portfolios demonstrating consistent, successful results.

A skilled contractor will evaluate your concrete’s condition, recommend the best finish for your environment, and deliver a floor that meets both performance and aesthetic goals.

Understanding Concrete Polishing Aggregate Levels

Aggregate exposure levels affect both the appearance and texture of the finished floor. The main options include:

- Cream Finish: A light grind that exposes minimal aggregate, showing mostly fine cement paste for a uniform, clean look.

- Salt-and-Pepper Finish: A medium grind that reveals small sand and stone particles, offering subtle depth and visual texture.

- Large Aggregate Finish: A deep grind that exposes larger stones, creating a bold, decorative effect often used in architectural or retail spaces.

Selecting the right level of exposure depends on the desired aesthetic, lighting, and overall design of the commercial space.

Cost Factors for Commercial Concrete Polishing

Project pricing varies depending on:

- Condition of the existing slab — cracks, coatings, or uneven surfaces may require additional prep work.

- Floor size — larger spaces increase labor and material needs but often reduce cost per square foot.

- Desired sheen and exposure level — higher gloss or deeper grind requires more polishing passes.

- Accessibility and location — job site logistics and regional cost differences also affect pricing.

Despite these variables, polished concrete typically remains one of the most economical long-term flooring solutions available, due to its lifespan and minimal maintenance requirements.

Maintenance Requirements for Polished Concrete Floors

Polished concrete is easy to maintain when following a simple routine:

- Dust mop daily to remove grit that could scratch the surface.

- Wet mop weekly using a neutral pH cleaner to lift residue and restore shine.

- Clean spills promptly, especially acidic substances, to avoid surface etching.

- Reapply a protective guard or sealer every few years to preserve gloss and protect against wear.

Following this regimen keeps the surface looking vibrant while maintaining its structural integrity and slip resistance.

Durability and Lifespan of Commercial Polished Concrete

When properly installed and maintained, polished concrete can last for decades — often matching the lifespan of the building itself. The combination of densification, polishing, and sealing strengthens the concrete, preventing surface dusting, cracks, and deterioration.

This longevity makes it an excellent investment for property owners seeking low lifecycle costs and consistent aesthetic performance over time.

Environmental Advantages of Polished Concrete

Polished concrete is one of the most sustainable flooring options available. The process uses the building’s existing concrete slab, eliminating the need for new materials or adhesives, and drastically reducing waste.

Its smooth, low-emission surface improves indoor air quality by eliminating VOCs and allergens. Additionally, the floor’s reflective finish enhances natural light distribution, reducing the need for artificial lighting and lowering energy consumption — an eco-conscious choice for LEED-certified and green building projects alike.

Partner with Premier Polishing Corp for Commercial Concrete Polishing in Long Island, NY

Elevate your commercial space with a polished concrete floor that delivers both form and function. Premier Polishing Corp provides expert concrete polishing, epoxy flooring, grind and seal, and overlay systems for businesses throughout Long Island, NY.

Our in-house civil engineers bring over 75 years of combined experience, supported by trained crews, advanced equipment, and top-tier materials to ensure exceptional quality and consistency.

We also design and craft custom concrete furniture — including countertops, sinks, and tables — bringing the same precision and craftsmanship to every project. From consultation to completion, Premier Polishing Corp delivers durable, beautiful floors built to impress and perform for years to come.